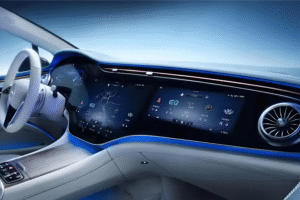

Introduction to TFT Displays in Automotive Applications

Thin Film Transistor (TFT) displays have become a quintessential aspect of modern automotive design, marking a significant shift from traditional analog interfaces to a more sophisticated digital environment. As vehicles evolve into complex systems requiring user-friendly interfaces, the demand for high-quality automotive TFT display specifications has surged. These displays are not only pivotal for providing essential information to drivers but also play a vital role in delivering a seamless user experience. Thin Film Transistor (TFT) displays have become a quintessential aspect of modern automotive design, marking a significant shift from traditional analog interfaces to a more sophisticated digital environment. As vehicles evolve into complex systems requiring user-friendly interfaces, the demand for high-quality automotive TFT display specifications has surged. These displays are not only pivotal for providing essential information to drivers but also play a vital role in delivering a seamless user experience.

The transition to TFT displays in automotive applications allows for enhanced visual clarity, vibrant colors, and improved responsiveness. Unlike conventional LCDs, automotive TFT displays utilize thin film transistor technology, which facilitates better pixel management and faster refresh rates. This capability ensures that drivers receive real-time information without lag, crucial for tasks such as navigation, monitoring vehicle performance, and accessing multimedia features.

The automotive industry’s increasing focus on digital integration has further fueled the adoption of industrial TFT LCD monitors. These displays are designed to meet rigorous specifications, including resistance to extreme temperatures and exposure to harsh environmental conditions, a requisite for automotive applications. A key characteristic of automotive TFT displays is their industrial-grade UV protection, ensuring that the displays remain functional and visually appealing over extended use, even when subjected to direct sunlight.

As drivers increasingly expect intuitive digital interactions, the integration of TFT displays has enabled the customization of interfaces, enhancing the overall driving experience. This trend is expected to continue as technological advancements push further enhancements in display functionality. By recognizing the significance of automotive TFT display specifications and operational considerations, stakeholders can proactively adapt to the evolving landscape, driving innovation within the vehicle interface domain.

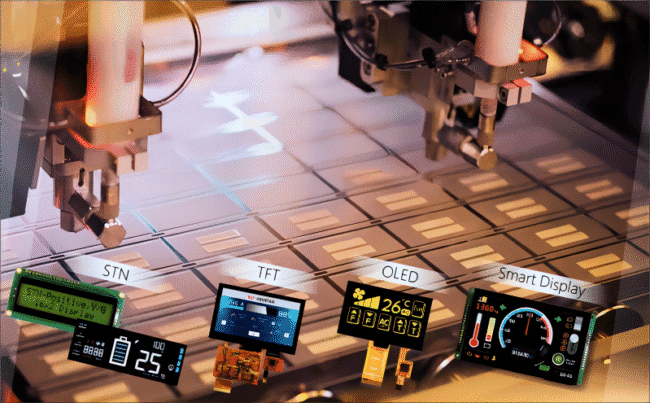

Product Reliability in Consumer vs. Industrial Displays

When evaluating automotive TFT display specifications and operational considerations, the reliability of display modules plays a critical role. Consumer LCDs, typically designed for home and office use, are characterized by their shorter product life cycles and limited resilience. In contrast, industrial TFT LCD monitors are engineered to endure harsh conditions, thus supporting longer operational lifespans. This distinction stems from the differing uses of these displays in everyday environments versus industrial settings.

Consumer LCDs are often produced using components that prioritize cost-effectiveness over performance durability, leading to susceptibility to environmental stressors such as temperature fluctuations, humidity, and vibrations. These factors can contribute to failures in consumer displays much faster than with their industrial counterparts. Automotive applications, which may require displays to function in extreme temperatures—from high heat to low cold—demand more robust solutions. Thus, automotive manufacturers often turn to industrial-grade products that are built to meet these rigorous environmental and operational demands.

The automotive TFT displays are expected to include features like industrial-grade UV protection, ensuring longevity even when exposed to direct sunlight over extended periods. Additionally, the functionality of such displays must allow for backward compatibility, benefiting users even in scenarios where specific models become discontinued. The importance of reliability in industrial display modules cannot be overstated; therefore, automotive manufacturers need to understand the specifications that ensure durability and performance.

Ultimately, the choice between consumer and industrial display options hinges on the specific requirements and application scenarios. For automotive implementations, investing in higher-quality, resilient displays will yield superior performance and reliability over time, thereby aligning with the industry’s operational considerations and expectations.

Operating Environment Challenges for TFT Displays

The automotive industry subjects TFT (Thin Film Transistor) displays to a wide array of environmental challenges that must be meticulously addressed to ensure reliability and performance. One of the primary factors influencing the automotive TFT display specifications is the operating temperature range. Automotive displays are often installed in environments that experience extreme fluctuations in temperature, from scorching heat in direct sunlight to frigid conditions during winter months. Thus, these displays must be designed to be resistant to high and low temperatures, mitigating risks of performance failures or display malfunctions.

Another significant concern is the impact of shock and vibration. Automotive environments inherently involve considerable movement and occasional abrupt jarring, such as traveling over rough terrain or in the event of a minor collision. For this reason, automotive TFT displays must demonstrate high resilience against these forces. Implementing robust mounting solutions and utilizing durable construction materials can help provide the necessary durability against these stress factors.

Electromagnetic interference (EMI) presents another challenge. Automotive electronics are often surrounded by numerous sources of electromagnetic fields, including other components and wiring. Consequently, automotive TFT displays must be designed to operate effectively without experiencing degradation in performance due to EMI. Attention to shielding and circuit design ensures optimal functionality in the presence of these disturbances.

Finally, mechanical damage can occur due to factors such as debris on the road or unintentional impacts. Industrial-grade UV protection must be considered to preserve the integrity of automotive displays, preventing fading, discoloration, and degradation of the viewing quality. Each of these operational considerations plays a vital role in developing TFT displays that meet the rigorous demands of automotive applications and enhance the dependability and user experience of these essential components.

Readability and Visibility Factors

When it comes to automotive TFT display specifications and operational considerations, readability and visibility are paramount. One of the most critical factors influencing these aspects is brightness. Displays that are adequately bright can significantly improve visibility under various lighting conditions, including direct sunlight. High brightness levels enhance the driver’s ability to read critical information without straining their eyes, resulting in improved safety during vehicle operation.

Another important factor is the contrast ratio. A higher contrast ratio allows for better differentiation between text and background, making it easier for users to interpret displayed information quickly. In automotive environments, where attention to detail is crucial for driving safety, ensuring that displays have optimal contrast ratios can reduce the chances of misreading vital information. This becomes essential when viewing graphs, navigation details, or alerts on the TFT screen while on the move.

Viewing angles also play a significant role in the usability of automotive displays. A wide viewing angle ensures that information remains legible from various positions, which is critical in multi-occupant scenarios. Transflective LCD technology serves as an innovative solution in this regard, as it enables the display to utilize ambient light efficiently, providing clear visibility without sacrificing performance even in less-than-ideal lighting conditions.

Lastly, industrial-grade UV protection is increasingly necessary for automotive TFT displays, particularly for those that incorporate anti-UV capacitive touch panels. Prolonged exposure to sunlight can lead to degradation of display quality and functionality if adequate UV protection is not in place. Ensuring that displays leverage proper protection measures not only enhances longevity but also maintains clarity and visual performance. Addressing these factors holistically contributes to optimal user experience and operational safety in the automotive sector.

Impact of UV Radiation on Touch Panels

Ultraviolet (UV) radiation poses significant challenges for touch panel technology, particularly in outdoor and semi-outdoor applications where exposure to sunlight is a persistent issue. Prolonged exposure to UV rays can lead to detrimental effects on the performance and durability of touch panels, especially those employing projected capacitive (PCAP) technology. One of the most common problems encountered is the yellowing of the display surface, which can obscure visibility and disrupt user interaction.

In addition to yellowing, the impact of UV radiation can manifest as bubbling or delamination within the layers of the touch panel, further compromising its structural integrity. These issues arise due to the breakdown of materials used in the touch panels when they are subjected to prolonged UV exposure, leading to a shorter operational lifespan and increased maintenance costs. The importance of addressing these challenges becomes paramount, particularly in automotive applications where reliability and responsiveness are critical.

To mitigate these effects, the selection of appropriate touch panel solutions is essential. Products, such as AMT’s anti-UV capacitive touch panels, are engineered specifically to resist UV damage. These industrial-grade components feature advanced coatings that can provide substantial protection against harmful UV radiation, thereby preserving the optical clarity and functionality of the display. Utilizing these robust solutions not only extends the operational life of the automotive TFT display but also aligns with the stringent automotive TFT display specifications and operational considerations by ensuring that the display performs optimally under variable environmental conditions.

In summary, understanding the impact of UV radiation on touch panels is crucial for making informed decisions regarding their application in automotive and industrial settings. The integration of advanced technologies such as anti-UV capacitive touch panels represents a proactive approach to enhancing product longevity and performance in the face of environmental challenges.

Temperature Resistance: Why It Matters

The operational environment of automotive TFT displays is one of the primary factors influencing their specifications. One of the most critical specifications is temperature resistance. Automotive LCD displays are frequently exposed to extreme temperatures, ranging from the intense heat of direct sunlight to the frigid cold of winter conditions. This temperature variance can significantly impact the performance and reliability of the displays, affecting visual quality, responsiveness, and overall durability.

The automotive industry mandates that TFT displays demonstrate resilience against temperature fluctuations. Displays that do not meet stringent automotive TFT display specifications may suffer from reduced functionality, such as screen dimming, pixel malfunction, or worse, total failure under extreme conditions. These consequences highlight the necessity of adopting industrial-grade components that can withstand these harsh environments, including robust industrial TFT LCD monitors that have been designed with these operational considerations in mind.

In terms of performance standards, automotive manufacturers often seek displays that adhere to rigorous testing protocols for temperature resistance. This includes testing under both high and low-temperature extremes, ensuring that the display can function correctly within the designated operating temperature ranges, typically between -40°C and +85 +85°C. Failure to meet these requirements can lead to not only performance issues but also potential safety risks for the vehicle’s operation.

Moreover, the integration of industrial-grade UV protection can further enhance the longevity and operational resilience of automotive LCDs. Such protection is instrumental in preventing degradation that may occur due to prolonged exposure to sunlight, which can add another layer of challenge to temperature management. In conclusion, addressing temperature resistance in automotive TFT displays is vital for ensuring that they maintain their performance and reliability in variable conditions, thereby supporting the need for stringent specifications and industry compliance.

Advancements in TFT Display Technology

The field of automotive displays has undergone significant advancements, particularly with Thin-Film Transistor (TFT) technology, which has become a cornerstone for modern vehicle systems. Innovations in automotive TFT display specifications have led to enhanced resolution, providing crisp imagery that enhances user interaction and drives safety. The transition from smaller screens typically found in mobile devices to larger TFT displays within vehicles is a direct response to the increasing demand for more interactive and informative interfaces. This evolution caters to the need for real-time data presentation, allowing drivers and passengers to access essential information without distraction.

One of the notable developments in TFT technology is the improvement in resolution capabilities, resulting in displays that offer Full HD and even 4K outputs. Such clarity plays a critical role in automotive applications, as clear graphics ensure that drivers can quickly interpret vital information displayed on their screens. Furthermore, advances in screen size have allowed manufacturers to integrate larger touch-enabled displays into dashboards, providing space for multi-functional user interfaces that can manage everything from navigation to vehicle diagnostics.

Touchscreen functionalities have also seen substantial enhancement, with modern automotive TFT LCD monitors offering improved responsiveness and durability. This is essential for maintaining usability in varying driving conditions, where quick access to information can be crucial for safety. Moreover, industrial-grade UV protection incorporated in these displays ensures long-term reliability despite exposure to sunlight and varying weather conditions. Such specifications are vital to the operational considerations of automotive displays, ensuring they maintain performance and longevity in fluctuating temperature ranges. Overall, the advancements in TFT display technology signify a major step forward in enhancing the driving experience through improved interactivity and information accessibility.

Use Cases of Ruggedized Displays in Various Industries

Ruggedized TFT displays have emerged as crucial components across multiple industries, owing to their resilience and ability to perform in challenging environments. In the automotive sector, for instance, the automotive TFT display specifications are meticulously engineered to withstand extreme temperatures, from scorching hot summers to frigid winters. This resilience ensures that critical driving information remains visible and operational, ultimately enhancing driver safety and comfort.

Marine systems also benefit from the use of ruggedized TFT displays, which are designed to endure harsh marine conditions, including saltwater exposure and high humidity. These displays provide vital navigational information and system monitoring in real-time, ensuring that both recreational and commercial vessels can operate effectively, regardless of weather patterns. The robustness of these industrial TFT LCD monitors is essential for maintaining functionality in extreme maritime environments.

Kiosks, frequently found in retail and transportation settings, utilize ruggedized displays to ensure uninterrupted service even in high-traffic areas. With their superior touch sensitivity and durability, these displays can operate seamlessly throughout the day, engaging customers while withstanding the rigors of intensive use. The adaptability of ruggedized displays within kiosks demonstrates their vital role in enhancing customer experience and operational efficiency.

Electric vehicle charging stations are another area where ruggedized TFT displays prove invaluable. Given that these stations often operate outdoors in variable weather conditions, the displays must be designed with industrial-grade UV protection to prevent screen degradation. This consideration not only extends the lifespan of the display but also ensures that users receive clear and accurate information when accessing charging services.

Across these diverse sectors, ruggedized TFT displays showcase remarkable versatility, demonstrating their essential role in supporting modern technology-driven environments. By meeting the specific demands of each industry, these displays enhance both performance and user experience.

Future Trends in Automotive Display Technology

The automotive industry is poised for significant transformation as display technology evolves to meet the demands of modern consumers. A key aspect driving this change is the integration of artificial intelligence (AI) into automotive TFT display specifications. This technology enables displays to learn and adapt to drivers’ preferences, enhancing user interaction with vehicle interfaces. As vehicles grow smarter, these AI-driven displays will provide tailored content and alerts, enabling a more intuitive driving experience.

In addition to AI, augmented reality (AR) is becoming increasingly relevant in automotive displays. By overlaying digital information onto the physical world, AR can significantly improve navigation and safety. For instance, heads-up displays (HUDs) can project essential information directly onto the windshield, allowing drivers to access data without taking their eyes off the road. Such innovations represent a substantial leap forward from traditional industrial TFT LCD monitors, aligning with contemporary trends requiring more user-focused interfaces in vehicles.

The advent of smart displays is also noteworthy. These displays not only provide vital operational considerations but can be synchronized with various smart devices, enabling seamless connectivity between the car and the user’s technology. This trend aligns with the growing consumer expectation for enhanced user experience and integration with smartphones and home automation systems.

Furthermore, the automotive industry’s commitment to employing industrial-grade UV protection in display technology is crucial for minimizing glare and ensuring readability in diverse weather conditions. As temperatures fluctuate, automotive LCD displays need to remain resilient in high and low temperatures, which also encompasses a range of environmental challenges.

Overall, the future landscape of automotive display technology will likely be characterized by a seamless fusion of AI, AR, and smart capabilities, ultimately leading to a more engaging and responsive driving experience. As these trends unfold, they will undoubtedly influence the specifications and operational considerations of next-generation automotive displays.